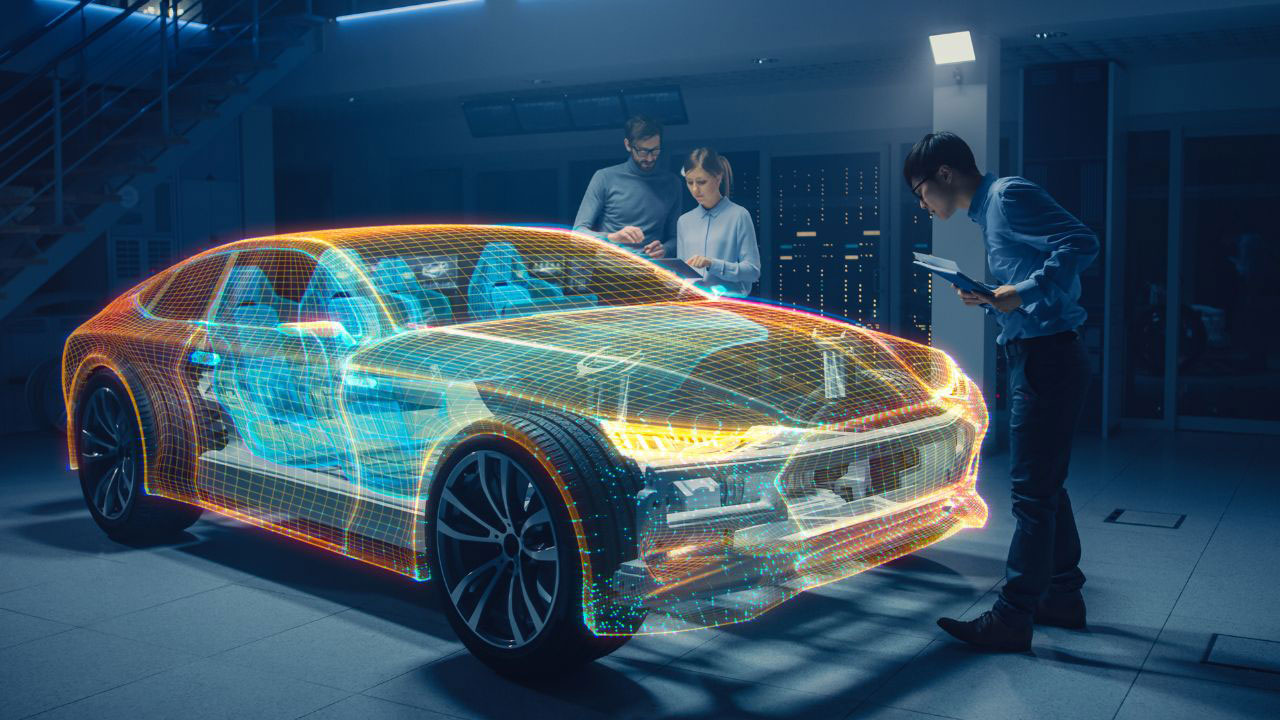

The concept of digital twins in EV production is revolutionizing the automotive industry. As electric vehicles (EVs) continue to gain popularity, the use of digital twins becomes increasingly important in streamlining production processes and improving vehicle performance. This advanced technology allows manufacturers to create a virtual replica of a physical asset, enabling them to simulate, analyze, and optimize every aspect of the vehicle’s lifecycle. By leveraging digital twins, automakers can enhance efficiency, reduce costs, and accelerate innovation.

In recent years, the adoption of digital twins in EV production has been on the rise. This technology not only aids in the design and manufacturing phases but also plays a critical role in maintenance and operational efficiency. As the automotive industry shifts towards electrification, the integration of digital twins is proving to be a game-changer, paving the way for smarter, more sustainable vehicles.

Understanding Digital Twins

A digital twin is a virtual representation of a physical object or system. In the context of EV production, it involves creating a detailed digital model of the electric vehicle, encompassing its components, systems, and processes. This model is continuously updated with real-time data from sensors and other sources, allowing manufacturers to monitor performance, predict maintenance needs, and make data-driven decisions.

Benefits of Digital Twins in EV Production

1. Enhanced Design and Prototyping

One of the primary advantages of using digital twins in EV production is the ability to enhance design and prototyping processes. By simulating different scenarios and configurations, manufacturers can optimize vehicle design, reduce development time, and ultimately bring products to market faster. This leads to significant cost savings and increased competitiveness in the rapidly evolving EV market.

2. Improved Manufacturing Efficiency

The integration of digital twins into manufacturing processes allows for improved efficiency and precision. By analyzing production data in real-time, manufacturers can identify bottlenecks, streamline workflows, and optimize resource allocation. This not only reduces production costs but also minimizes waste and environmental impact.

3. Predictive Maintenance and Reliability

Digital twins play a crucial role in predictive maintenance, enabling manufacturers to identify potential issues before they become costly problems. By monitoring real-time data and analyzing historical patterns, manufacturers can predict component failures, schedule maintenance activities, and ensure optimal vehicle performance. This proactive approach enhances reliability, reduces downtime, and improves customer satisfaction.

Applications of Digital Twins in EV Production

1. Battery Management

Battery management is a critical aspect of EV production, and digital twins offer valuable insights into battery performance and health. By simulating various scenarios and analyzing data from sensors, manufacturers can optimize battery efficiency, extend lifespan, and improve overall vehicle range. This technology also aids in the development of advanced battery management systems, ensuring safe and reliable operation.

2. Vehicle Dynamics and Performance

Digital twins enable manufacturers to simulate and analyze vehicle dynamics and performance under different conditions. By testing virtual models in various driving scenarios, automakers can fine-tune suspension systems, aerodynamics, and energy consumption. This results in improved handling, efficiency, and overall driving experience for EV owners.

3. Quality Control and Testing

In the realm of quality control and testing, digital twins provide a comprehensive solution for ensuring product reliability and compliance with industry standards. By replicating real-world conditions and stress-testing virtual models, manufacturers can identify potential defects and make necessary improvements before production begins. This reduces the risk of recalls and enhances customer satisfaction.

Challenges and Future Outlook

While the benefits of digital twins in EV production are undeniable, there are several challenges that manufacturers must address. One of the primary concerns is data security and privacy, as the exchange of sensitive information between virtual and physical systems can pose risks. Additionally, the implementation of digital twins requires significant investment in technology infrastructure and expertise.

Looking ahead, the future of digital twins in EV production is promising. As technology continues to advance, we can expect even more sophisticated models and applications. With the integration of artificial intelligence and machine learning, digital twins will become smarter and more autonomous, driving further innovation and efficiency in the automotive industry.

Conclusion

The adoption of digital twins in EV production marks a significant milestone in the evolution of the automotive industry. By leveraging this technology, manufacturers can optimize design, enhance manufacturing processes, and improve vehicle performance. As the demand for electric vehicles continues to grow, the role of digital twins will become increasingly vital in shaping the future of transportation.

For more insights on the rapid growth in EV technology, you can read this blog post.

Frequently Asked Questions

1. What are digital twins?

Digital twins are virtual replicas of physical objects or systems used to simulate and analyze real-world performance and behavior.

2. How do digital twins benefit EV production?

Digital twins enhance design, manufacturing efficiency, predictive maintenance, and vehicle performance, leading to cost savings and improved customer satisfaction.

3. What are some challenges of implementing digital twins in EV production?

Challenges include data security, privacy concerns, and the need for significant investment in technology infrastructure and expertise.